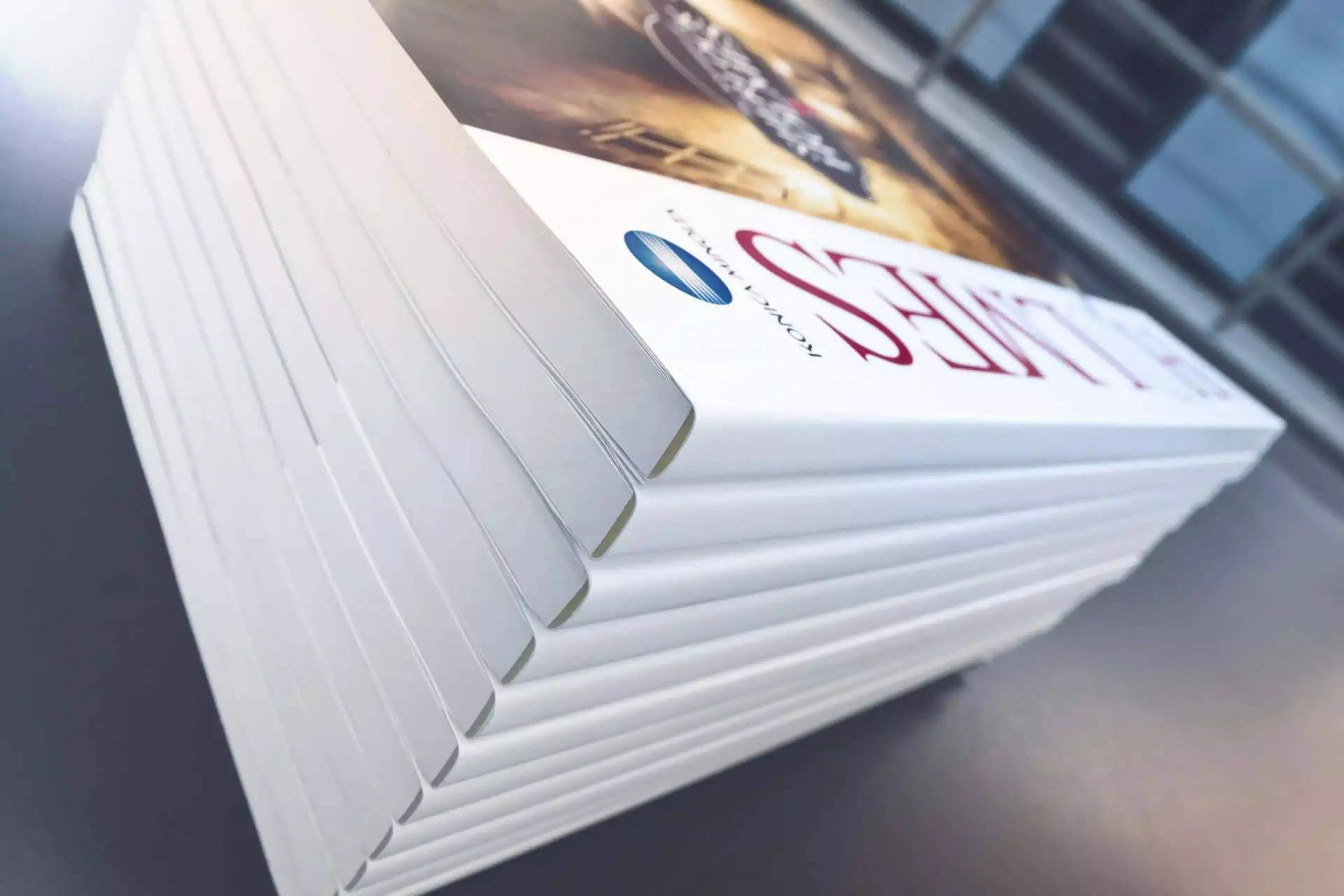

Povećajte profit, skratite vreme proizvodnje i istaknite proizvod – uz linijsku završnu obradu

Pružanje mogućnosti linijske završne obrade omogućava vam da povećate profitne marže za zadatke štampe, uz istovremeno skraćivanje vremena proizvodnje, smanjivanje troškova rada, poboljšavanje kontrole kvaliteta, smanjivanje količine otpada i uštedu energije.

Iako se tradicionalno posmatralo kao zakasnela stvar i usko grlo u proizvodnji, završna obrada sada predstavlja kritičnu fazu u proizvodnji i način za isticanje proizvoda i stvaranje dodate vrednosti. Nije neobično da na završnu obradu odlazi čak do 40% troškova proizvodnje, kao i da loša kontrola kvaliteta u ovoj fazi uništi veliki deo dodate vrednosti.

Uz napredovanje tehnologije digitalne proizvodnje, male i srednje štamparije shvatile su da relativno skromno ulaganje u opremu za završnu obradu može da dovede do značajnih poboljšanja produktivnosti i smanjivanja troškova. Rezultati iz skorašnjeg drupe izveštaja o globalnim trendovima pokazuju da je 48% učesnika planiralo da investira u opremu za završnu obradu, kao i da 40% investira sa ciljem povećavanja efikasnosti.

What exactly is ‘inline finishing’?

Inline finishing is the process of bringing services such as folding, saddle stitching, side stitching, case binding, punching and other post-processes in-line, so they are accomplished at the same time as the printing. A wide array of finishing equipment is now available to be connected directly to digital production printers to achieve this,

Providing these services in-line not only saves on labour costs; it also prevents missing pages, imperfect collation, and other common mishaps. It makes printing extremely small lots possible – even a single copy – and extends the range of just-in-time services from fliers to catalogues, manuals and other high page-count projects.

Inline finishing in the print industry gives you benefits including:

- Labour-intensive post-processing completed at same time as printing

- One-pass production of high page-count materials

- Flawless binding, free of missing pages and imperfect collation

Inline finishing is the process of bringing services such as folding, saddle stitching, side stitching, case binding, punching and other post-processes in-line, so they are accomplished at the same time as the printing. A wide array of finishing equipment is now available to be connected directly to digital production printers to achieve this,

Providing these services in-line not only saves on labour costs; it also prevents missing pages, imperfect collation, and other common mishaps. It makes printing extremely small lots possible – even a single copy – and extends the range of just-in-time services from fliers to catalogues, manuals and other high page-count projects.

Inline finishing in the print industry gives you benefits including:

- Labour-intensive post-processing completed at same time as printing

- One-pass production of high page-count materials

- Flawless binding, free of missing pages and imperfect collation

What exactly is ‘inline finishing’?

Which inline finishing workflow do I need?

Digital inline finishing features a variety of different workflows

These are all about automation, making in-line and near-line equipment critical, but sometimes an offline approach will be more applicable.

So how should you be investing? In inline finishing, the press and inline finishing equipment are directly connected and closely integrated using front-end management controls. This is the solution for you if you produce a defined range of products in standard formats such as stitched booklets, reports, calendars and book blocks. The overall productivity of a digital press with in-line finishing capability is determined by the speed and efficiency of the finishing components, so it is essential that these don’t detract from the rated speed of the digital press.

An offline finishing workflow is more common when a printer has a range of digital and offset equipment, but this increases labour costs. Sometimes the higher speed of off-line finishing equipment will more than compensate for the increased operator invention. It all depends on the type and quantity of jobs you need to finish.

In contrast to in-line and off-line, near-line offers greater flexibility. There is no physical connection between equipment in this case, but the finishing line knows the requirements of each job, from OMR (optical mark recognition) technology or from a direct interface with the press’s print server, through JDF. This enables the finishing line to manage the printed output from a variety of presses and create an audit trail, which is critical to personalized products like mailshots or transactional documents.

Choosing the right finishing workflow will depend on understanding not only your workload, but also how you can apply different finishing solutions to improve efficiencies and add value through new products. However one major benefit that has been largely overlooked by the printer and has not been sold effectively to the customer is inline finishing.

What exactly is ‘inline finishing’?

Digital inline finishing features a variety of different workflows

These are all about automation, making in-line and near-line equipment critical, but sometimes an offline approach will be more applicable.

So how should you be investing? In inline finishing, the press and inline finishing equipment are directly connected and closely integrated using front-end management controls. This is the solution for you if you produce a defined range of products in standard formats such as stitched booklets, reports, calendars and book blocks. The overall productivity of a digital press with in-line finishing capability is determined by the speed and efficiency of the finishing components, so it is essential that these don’t detract from the rated speed of the digital press.

An offline finishing workflow is more common when a printer has a range of digital and offset equipment, but this increases labour costs. Sometimes the higher speed of off-line finishing equipment will more than compensate for the increased operator invention. It all depends on the type and quantity of jobs you need to finish.

In contrast to in-line and off-line, near-line offers greater flexibility. There is no physical connection between equipment in this case, but the finishing line knows the requirements of each job, from OMR (optical mark recognition) technology or from a direct interface with the press’s print server, through JDF. This enables the finishing line to manage the printed output from a variety of presses and create an audit trail, which is critical to personalized products like mailshots or transactional documents.

Choosing the right finishing workflow will depend on understanding not only your workload, but also how you can apply different finishing solutions to improve efficiencies and add value through new products. However one major benefit that has been largely overlooked by the printer and has not been sold effectively to the customer is inline finishing.

Inline Finishing

Differentiate your product hugely and create stronger customer loyalty

Inline Finishing means your customers will benefit from already-finished print products, shorter production deadlines for more complex print products and a ‘one-stop shop’ offering everything from a single source.

For smaller printers and in-house print departments, reducing the amount of work that is outsourced gives greater production flexibility and control. (A good example of this are W2P systems, providing a steady but unpredictable flow of digital short run on-demand jobs, which cannot be outsourced and have to be completed in-house.)

Essentially, the more aspects of a print job you can control internally and offer on-demand, the greater your growth will be and the more customer loyalty you will generate.

Increased profit margins

The ability to offer all-in-one print solutions

Energy Savings

Fewer machine setups

Greater flexibility in production

Improved Quality Control

Less Waste

Lower Labour Costs

Shorter Production Times

Konica Minolta hardver za štampanje

Hardver

Želite vrhunske performanse digitalne proizvodne štampe? Upravo ste ih pronašli. Hardver za proizvodno štampanje i kancelarijski hardver kompanije Konica Minolta predstavljaju reference u industriji, uz uređaje koji pružaju revolucionarni kvalitet slika u boji, izuzetno brzo crno-belo štampanje, opcije linijske završne obrade profesionalnog kvaliteta koje odgovaraju složenim specifikacijama vaših zadataka i još toga. Bez obzira na širinu oblasti specijalizacije vaše kompanije, naš hardver za štampanje omogućava vam da izgradite infrastrukturu za štampu, upravljate digitalnim sadržajem, instalirate vrhunske merne instrumente i da istražujete druga rešenja dizajnirana kako biste iz korena promenili radni proces.

Konica Minolta softverski proizvodi

Softver

Istražite bezbrojne načine na koje softverski proizvodi kompanije Konica Minolta mogu da unaprede vaše operacije. Konica Minolta rešava probleme vaše kompanije, prilagođava se različitim stilovima rada i nudi softverska rešenja koja odgovaraju na potrebe vaše branše. Stalnim davanjem prioriteta vašim potrebama, Konica Minolta odgovara na softverske zahteve čak i najzahtevnijih globalnih organizacija. Korišćenje ovog sistema omogućava vam da kontrolišete troškove za svaki odštampani i kopirani otisak, da kreirate napredne bezbednosne mere kako biste bili sigurni da osetljivi dokumenti neće doći do neovlašćenih osoba i još toga.

Uvek vama na usluzi

Usluge

Naše iskusno i obrazovano specijalizovano osoblje odgovoriće na sva vaša pitanja i pokazati vam kako da koristite proizvod. Naše usluge rade vama u koristi, u okviru sistema podrške osmišljenog tako da garantuje da ćete vi i vaša kompanija moći u potpunosti da iskoristite rešenja. Nudimo asortiman različitih usluga, uključujući optimizovane usluge štampe u kombinaciji sa konsultacijama; implementaciju hardvera i softvera; upravljanje radnim procesom radi smanjivanja potrošnje na dokumente; i pametne bezbednosne usluge za zaštitu vašeg poslovanja.