Digitalna tehnologija – licenca za štampanje nalepnica?

Digitalna proizvodnja nalepnica je u veoma brzom rastu. Da biste iskoristili taj rast, uživajte u novim pogodnostima koje pruža digitalna tehnologija i održite profitabilnost analogne proizvodne opreme, uz prelazak pomoću komplementarnog pristupa kompanije Konica Minolta uslugama štampanja.

Profesionalno odštampane nalepnice u današnje vreme predstavljaju ozbiljan posao. Veoma ozbiljan. Kompanijama iz različitih branši potrebno je da identifikuju i istaknu svoje proizvode i brendove; prilagođene nalepnice mogu da se koriste na uzbudljive nove načine, pa se količina odštampanih kvadratnih metara u ovom sektoru skoro udvostručila tokom proteklih nekoliko godina. Čak i u ovoj onlajn eri, dizajn nalepnice igra izuzetno važnu ulogu u prihvatanju proizvoda. Nalepnica ili etiketa na boci ili ambalaži odražava poruku i identitet brenda.

Najnovije cifre instituta za marketinška istraživanja Smithers Pira pokazuju da je količina odštampanih kvadratnih metara u ovom sektoru porasla sa 4 milijarde 2014. na 7 milijardi 2017.

Šta je štampanje nalepnica?

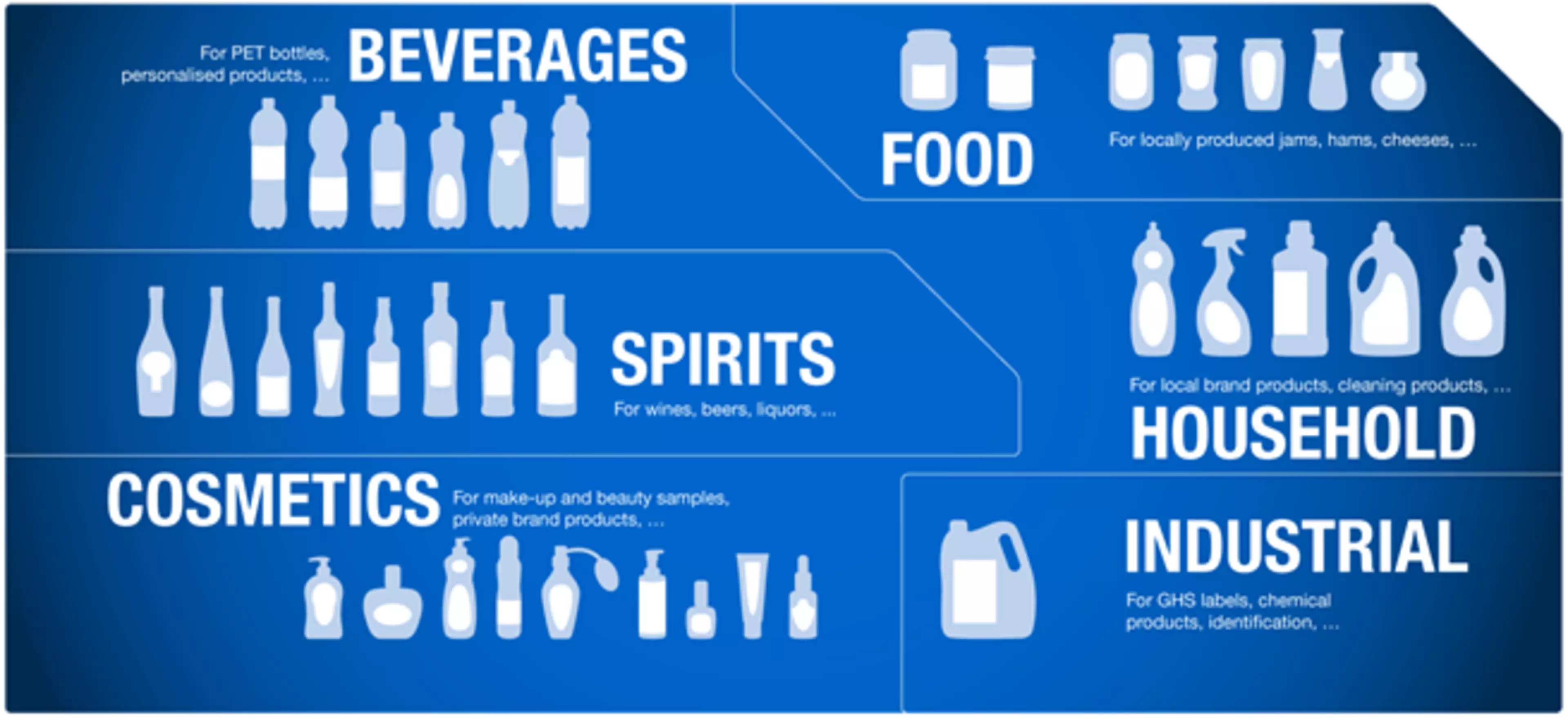

U današnje vreme bilo bi nemoguće da sektori maloprodaje, trgovine, industrije i distribucije funkcionišu bez nalepnica. One se sa raznobojnim ilustracijama nalaze na skoro svemu što kupujemo u prodavnicama, apotekama, prodavnicama sa alatom, pa čak i u hipermarketima i baštenskim centrima izvan gradova – bez obzira na to da li proizvodi unapred zapakovani u bočice, tube, tegle, posude, činije ili druge vrste kontejnera, umotani u foliju, pa čak i postavljene direktno na artikle kao što su kosilice, reketi za tenis, odeća i hardver.

Nalepnice su osnovni medij koji može da se koristi za identifikovanje i kao pomoć pri plasiranju svih vrsta robe, kao i za pružanje osnovnih informacija za korisnike ili pravnih informacija, kao što su masa ili zapremina, detalji za kontaktiranje sa dobavljačem ili proizvođačem, lista sastojaka i informacije o odlaganju, rukovanju, zdravoj ishrani, korišćenju ili bezbednosti.

Pored ovoga, skoro sve nalepnice u današnje vreme sadrže barkod – šablon sa crnim i belim linijama koji se skenira prilikom automatizovanog plaćanja – za identifikovanje artikala i njihovih cena na računu. Nalepnice sa barkodovima različitih vrsta takođe se koriste u sektorima proizvodnje, manipulisanja, transporta i distribucije, za razne načine primene, kao što su sklapanje i fabrička automatizacija, identifikovanje delova i komponenti i praćenje kroz lanac nabavke.

Inovacije na polju nalepnica tokom skorašnjih godina takođe su dovele do porasta broja specijalnih tipova nalepnica koje omogućavaju interakciju sa mobilnim telefonima radi pristupanja veb lokacijama, pružanja dodatnih informacija kupcima, učestvovanja u takmičenjima, igranja igara ili registrovanja za društvene mreže. Neke nalepnice su čak i jedinstveno promenljive ili personalizovane.

Ukratko, nalepnice su postale osnovna komponenta svakodnevnog modernog života, u ovom ili onom obliku. Ne čudi onda to da nalepnice svih vrsta predstavljaju jedan od sektora sa najbržim rastom u industriji štampe, zajedno sa fleksibilnom ambalažom, uz prosečni globalni godišnji rast od 4–6% bar tokom proteklih 30 godina (procenjuje se da je trenutna stopa rasta 4,7%) i skoro stalni rast veći od bruto domaćeg proizvoda. Na globalnom nivou, nalepnice proizvodi usko specijalizovani sektor štamparske industrije čiji je trenutni obrt veći od 60 milijardi USD.

Preuzmite whitepaper potpuno besplatno:

The benefits of label printing

Digital label presses

The label printing sector has grown to such an extent that annual installations of digital label presses are now close to 30% of all narrow-web press installations worldwide, with over 3,000 digital label presses installed worldwide in the label industry at the end of 2015.

Looking ahead, digital label presses are forecast to make-up close to 40% or more of all annual narrow-web press installations by 2020.

Against this backdrop, the overall value of digitally printed label jobs nowadays is viewed as far greater than the printed cost alone. Industry estimates indicate that although digital label printing is currently only about 3% to 5% of all printed pressure-sensitive label jobs by volume, it makes up some 15% to 18% or more of all print jobs by value.

The many benefits of this growing sector include:

Seamless workflow

A seamless workflow has become one of the essentials of successful digital label production. It provides the basis for minimizing errors and paperwork, speeds up response times, and provides continually up-dated manufacturing and customer information, as well as bringing down lead times.

Cost efficiencies

Compared to conventional label printing, the digital process does not use printing plates, or have any platemaking materials, chemicals, processes or time requirement, saving you money.

Production benefits

For the brand owner, the opportunity to reduce or eliminate label warehousing, reduce time to market, and improve supply chain efficiencies can be a compelling reason to turn to digital label production. The possibility of just-in-time production, short-run proofing and test marketing of labels is also of great interest.

Marketing opportunities

New added value and marketing opportunities for brand owners – indeed almost any size business ‒ have become a real focus for label users in today's ever-competitive environment. There are many examples of where digital printing solutions have provided the possibility to easily produce multiple versions or variations, variable design images, personalized labels, mass customization, new promotional opportunities and even regional, seasonal or special event labels. For the digital label producer these marketing opportunities offer the potential to add value and enhance profitability.

Environment and sustainability

There is little doubt that the environment and sustainability have become important issues. By producing exact quantities rather than a percentage of 'overs', digital printing reduces print wastage. Unlike other printing processes, there are also no chemicals, water, or plate making materials used with digital printing.

Brand security

A relatively new, but growing area for digital design and printing with the latest software solutions is to incorporate security design backgrounds and special features, variable images, micro text, anti-copy features and much more.

Track and trace

The fact that digital labels can be printed individually means printers can produce sequentially numbered or coded labels, create hidden codes matched to visible codes, and provide changing codes that can be used with smartphone technology – all offering new possibilities for track and trace label solutions.

Digital label presses

The label printing sector has grown to such an extent that annual installations of digital label presses are now close to 30% of all narrow-web press installations worldwide, with over 3,000 digital label presses installed worldwide in the label industry at the end of 2015.

Looking ahead, digital label presses are forecast to make-up close to 40% or more of all annual narrow-web press installations by 2020.

Against this backdrop, the overall value of digitally printed label jobs nowadays is viewed as far greater than the printed cost alone. Industry estimates indicate that although digital label printing is currently only about 3% to 5% of all printed pressure-sensitive label jobs by volume, it makes up some 15% to 18% or more of all print jobs by value.

The many benefits of this growing sector include:

Seamless workflow

A seamless workflow has become one of the essentials of successful digital label production. It provides the basis for minimizing errors and paperwork, speeds up response times, and provides continually up-dated manufacturing and customer information, as well as bringing down lead times.

Cost efficiencies

Compared to conventional label printing, the digital process does not use printing plates, or have any platemaking materials, chemicals, processes or time requirement, saving you money.

Production benefits

For the brand owner, the opportunity to reduce or eliminate label warehousing, reduce time to market, and improve supply chain efficiencies can be a compelling reason to turn to digital label production. The possibility of just-in-time production, short-run proofing and test marketing of labels is also of great interest.

Marketing opportunities

New added value and marketing opportunities for brand owners – indeed almost any size business ‒ have become a real focus for label users in today's ever-competitive environment. There are many examples of where digital printing solutions have provided the possibility to easily produce multiple versions or variations, variable design images, personalized labels, mass customization, new promotional opportunities and even regional, seasonal or special event labels. For the digital label producer these marketing opportunities offer the potential to add value and enhance profitability.

Environment and sustainability

There is little doubt that the environment and sustainability have become important issues. By producing exact quantities rather than a percentage of 'overs', digital printing reduces print wastage. Unlike other printing processes, there are also no chemicals, water, or plate making materials used with digital printing.

Brand security

A relatively new, but growing area for digital design and printing with the latest software solutions is to incorporate security design backgrounds and special features, variable images, micro text, anti-copy features and much more.

Track and trace

The fact that digital labels can be printed individually means printers can produce sequentially numbered or coded labels, create hidden codes matched to visible codes, and provide changing codes that can be used with smartphone technology – all offering new possibilities for track and trace label solutions.

The benefits of label printing

Why digital label printing creates new business

New opportunities

Digital label printing also brings in more business for the converter's conventional printing presses, while creating new opportunities in the shorter run and niche unsupported film markets for sleeves and flexibles. Around 14% of label converters that have invested in digital presses now also produce profitable shorter-run, mid- to narrow-web flexible packaging – sachets, pouches, tubes, pot lids, wrappers, bags and flexibles – for customers who started out on labels alone.

The benefits of label printing

New opportunities

Digital label printing also brings in more business for the converter's conventional printing presses, while creating new opportunities in the shorter run and niche unsupported film markets for sleeves and flexibles. Around 14% of label converters that have invested in digital presses now also produce profitable shorter-run, mid- to narrow-web flexible packaging – sachets, pouches, tubes, pot lids, wrappers, bags and flexibles – for customers who started out on labels alone.

Label Printing

Technology of the future meets benefits of the present

Konica Minolta offers an easy-to-use suite of quality software and hardware that lets you enjoy all the benefits of new digital technology with none of the potentially negative effects of transition.

It's designed to give you the technology of the future – without having to sacrifice the benefits of the present.

All the features you need (and one or two more)

Konica Minolta's powerful mix of software and hardware solutions has been created with one objective in mind: to enable your company to move seamlessly from analogue to digital processing, lock your printing business solidly into the booming profits of the label design of the future, and enjoy the maximum benefit and added value of digital.

Our features will let you offer your clients personalisation, lower your running costs, simplify your operation and put together your own seamless, customised version of the transition to digital. You can offer shorter run-lengths, flexible delivery times and much more. At the same time, those trusted analogue presses will just keep on running with our product mix. In short, our features let you enjoy all the benefits of the new technology while keeping your existing analogue plant profitable as you transition. So what are those features? The benefits to your company of our digital label printing product mix include:

Da li treba da se prebacim na digitalno? Saznajte sa Digital1234

Za konvencionalne konvertore analognih oznaka koji žele da prvi put investiraju u štampanje digitalnih etiketa, iza odluke je više nego samo kupovina nove štamparske mašine ili procesa. Za to je potrebno mnogo vrednovanja i razmišljanja, uključujući odluke o ljudima, prodaji i marketingu, sposobnosti za štampanje i upravljanje bojama u svakoj pojedinačnoj kompaniji.

Identifikujte, procenite, opravdajte i implementirajte

Ulaganje u štampanje digitalnih etiketa znači povlačenje unazad i kritični osvrt na način na koji poslujete i kako se povezujete kroz radni lanac i sa svojim klijentima. Za zauzete štampače etiketa i konvertore koji žele da prvi put ulažu u tehnologije digitalne štampe, izazov je često da znaju koja pitanja treba postaviti sebi, ko u kompaniji treba da bude uključen u proces donošenja odluka, i koje su implikacije za druga odeljenja, ili čak za kupce.

Kako bi pomogla kompanijama u njihovom razmišljanju i donošenju odluka, Konica Minolta je dizajnirala Digital1234 vodič za procenu. Ovaj poslovni razvojni program je upitnik zasnovan na poslovanju koji pokriva čitav niz ključnih poslovnih tema; korišćenjem jednostavnog i vizuelnog sistema 'semafora', procena vam pomaže da brzo identifikujete oblasti vašeg poslovanja koje bi mogle imati koristi od prelaska na digitalno istraživanje istražujući svaku pojedinačnu poslovnu priliku. Fokusira se na specifične potrebe konvertora etiketa i kompanija koje se bave grafičkim poljima.

Ispitujući područje kao što je Vaše postojeće poslovanje, kako možete generisati novi posao ulaganjem u digitalni rad, razumevanje Vašeg zaposlenog o digitalnom otisku i upravljanje digitalnim produkcijskim okruženjem, Digital1234 plan u četiri koraka - Identifikacija, procna, opravdanje i implementacija - sigurno će Vam reći da li je pravo vreme da vaša organizacija pređe na digitalno.

Ova četiri koraka su:

Ulaganje u rast i profitabilnost - Uloga digitalne štampe u svetu etiketa

Brzo prihvatanje i ulaganje u digitalnu štampu imalo je veliki uticaj na brz rast štampanja etiketa, promenu načina dizajniranja i proizvodnje prilagođenih etiketa i načina na koji se mogu koristiti na nove uzbudljive načine, kao što su etikete za vino, etikete hrane i boca za vodu.

How we help Firus Druck to impress their customers

Firus Druck, a traditional label printer from a renown German wine region (Mosel), was looking for the right solution for their customers demand of self-adhesive wine labels. They invested in a Konica Minolta AccurioLabel 190 and a GM DC330Mini as well as a GM HOTFB330 Standalone Hot Foil.The video describes how the investment is part of a wider strategy for our customers’ growth and development. It is about embracing new technologies and change within the ever-changing printing market.

oblikovanje štampanog materijala.

Prokom je Konica Minolta Korisnička Zajednica gde možete pronaći istraživanje tržišta, informacije i praktične alate, koji će Vam pomoći da postanete bolje informisaniji, produktivniji i na kraju profitabilniji. Mi u Prokomu smatramo da se ne radi samo o onome što ste napravili, već o tome šta omogućavate

Colours are processed at a resolution of 1,200 dpi x 8 bit with 256 gradations expressed in 1 pixel

Image density control technology

No pre-coating of media required

Operation is intuitive by following on-screen instructions; no need for extensive user training

Per-minute speeds of 23.4 m, 18.9 m, 13.5 m and 9.45 m can be selected to match the media used

Simitri® HD E toner technology

Tasks such as colour adjustments that are highly time-consuming on analogue now take seconds

The 3-dimensional hybrid structure that incorporates functional polymers provides high performance for all media types

Make the move from analogue to digital printing – painlessly

Hardver

Recent surveys of the industry suggest the most significant business 'pain points' for label converters are shorter lead times, and finding qualified press operators. So if you're looking for a one-stop shop to solve both these 'growing pains' at once, moving your company seamlessly from conventional to digital label production, opening you up to vast new digital markets and creating small batches of high-quality labels and stickers with a speed and flexibility your customers will talk about, the AccurioLabel 190 is the digital press for you.

You do the printing. Let us do the impositioning.

Softver

With its PDF-based workflow and generous feature set, AccurioPro Label Impose is an impressive tool indeed. This software lets operators handle a wide range of pre-press tasks from a single control station, can be married seamlessly with our AccurioLabel 190 hardware, and is the perfect complement to Konica Minolta's label press. The missing piece in your digital label printing puzzle.The only digital label printing software you'll ever need.

Always at your Service

Usluge

Our experienced, knowledgeable specialist staff will answer any questions you may have, and show you how to operate your product. Our services function for your benefit, within a support system designed to ensure you and your company benefit fully from the solutions. We offer a range of different services, including optimised print services to combine your consulting; hardware and software implementation; workflow management to lower your document spending; and smart security services, to keep your business safe.